Why investing in pallet wrapping machine repair supports workflow efficiency

Wiki Article

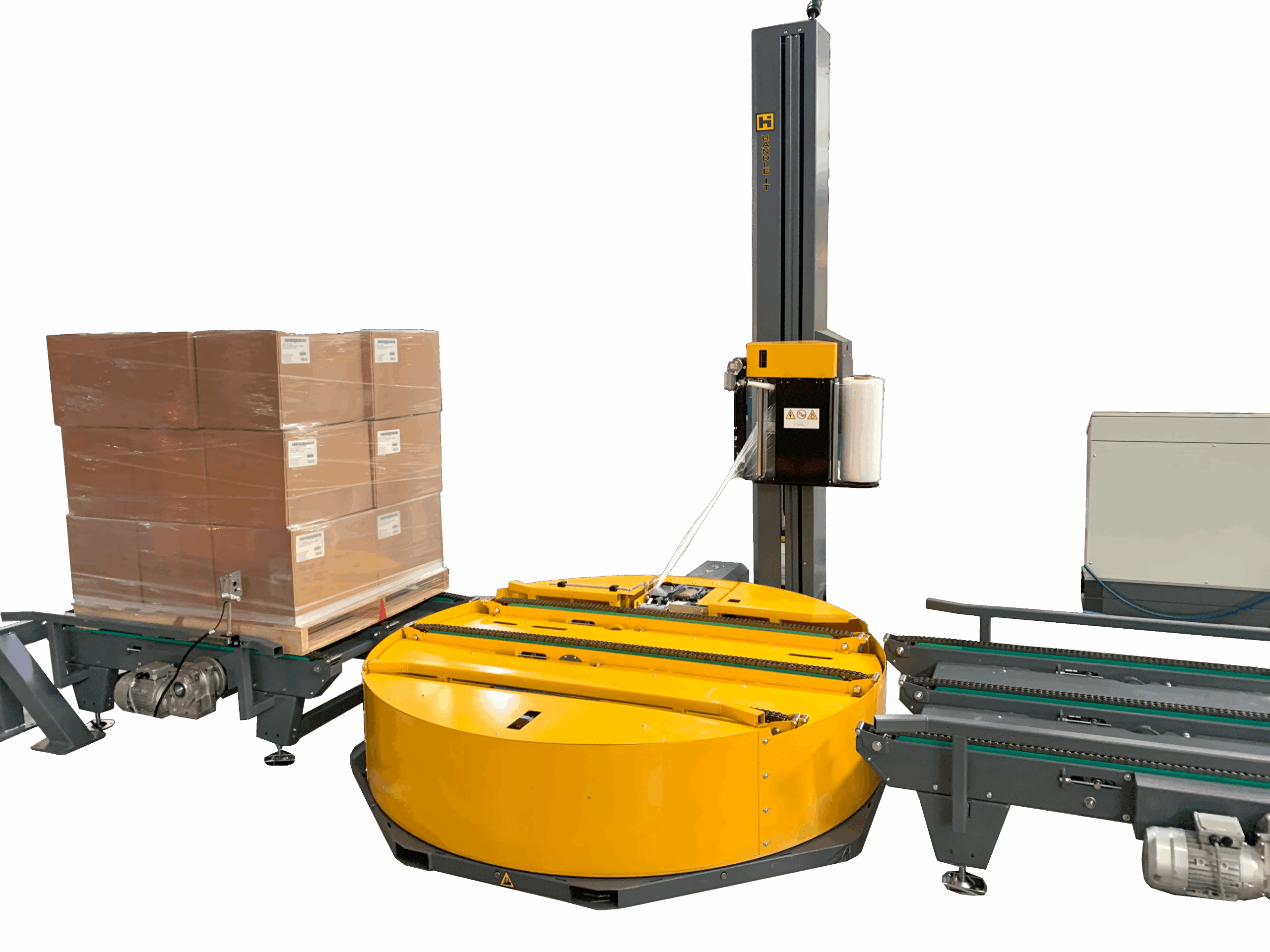

Exactly How to Maximize Performance With a Pallet wrapping Machine: Usual Repair Tips

Maximizing effectiveness with a pallet wrapping machine calls for a strategic technique to upkeep and repair. Routine checks are necessary to assure all elements operate smoothly. Common concerns such as irregular film stress and jamming can disrupt procedures. Addressing these troubles quickly can improve efficiency. Comprehending the subtleties of readjusting tension and preserving cleanliness is similarly important. What certain steps can be required to ensure peak performance?

Routine Upkeep Checks

Regular maintenance checks are vital for making sure the optimal efficiency of a pallet wrapping machine. These checks not only improve the long life of the tools however additionally enhance operational performance. Routine examinations should consist of examining the machine's electric elements, ensuring that all links are cost-free and protected from corrosion. The film dispensing system should be looked for correct positioning and stress to prevent operational interruptions. Additionally, oiling relocating components minimizes rubbing and wear, keeping smooth capability. Operators ought to likewise inspect the control panel for any type of abnormalities in readings or performance. Routine maintenance cultivates a positive technique to devices treatment, inevitably causing minimized downtime and boosted performance in the wrapping process. Abiding by an arranged maintenance plan is vital for optimal performance.Fixing Usual Issues

Changing Worn-Out Parts

Changing damaged parts is vital for maintaining the ideal efficiency of a pallet wrapping maker. Normal assessments assist determine components that show indicators of wear, such as the film carriage, rollers, or drive belts. These components can break down gradually, leading to inadequacies in wrapping procedures. It is vital to select high-quality components that match the equipment's specs to guarantee compatibility and peak performance when substitute is required. Service technicians should comply with the manufacturer's guidelines during the substitute process, as improper installation can result in further concerns. Additionally, keeping a supply of commonly required components can lessen downtime, enabling quicker repair services and maintaining efficiency levels. Aggressive maintenance and prompt replacements are vital to expanding the maker's lifespan.Readjusting Tension and film Setups

Maintaining excellent efficiency of a pallet wrapping equipment extends past changing damaged parts; it likewise includes make improvements the tension and film setups. pallet wrapping machine repair. Proper stress is important for achieving ideal load stability throughout transportation. If the tension is as well tight, it may harm the load, while inadequate stress can lead to loosened wrapping and potential shifting. Operators ought to regularly check and change the stress setups according to the certain requirements of the load being wrappedIn addition, selecting the right film kind and density is vital for pop over to this web-site guaranteeing reliable wrapping. Thicker movies use boosted toughness but may need higher tension settings. Alternatively, thinner films may be more affordable yet can jeopardize load security otherwise appropriately tensioned. Normal adjustments will certainly optimize performance and reduce product waste.

Maintaining the Equipment Tidy and Moisturized

Although frequently ignored, keeping the pallet wrapping maker tidy and lubed is necessary for ensuring peak performance and durability. Normal cleansing helps prevent the build-up of dirt, particles, and residue that can prevent mechanical functions. It is recommended to clean down surfaces and eliminate any built up find more materials after each use. In addition, appropriate lubrication of relocating parts minimizes rubbing, decreases wear, and expands the life expectancy of the equipment. Operators must speak with the maker's standards for advised lubricating substances and upkeep timetables. Performing regular evaluations to identify any type of indications of corrosion or corrosion can additionally avoid more considerable problems down the line. Following these practices will not just enhance efficiency yet additionally promote risk-free procedure of the pallet wrapping equipment.Frequently Asked Questions

Exactly how Commonly Should I Change the Pallet wrapping film?

The regularity of changing pallet wrapping film depends upon use and wear. pallet wrapping machine repair. Usually, it needs to be changed when indications of damage, splits, or extreme extending take place, making sure ideal efficiency and security of the covered productsCan I Utilize Different Sorts Of Films With My Device?

Various kinds of films can typically be utilized with Going Here pallet wrapping equipments, but compatibility depends on the equipment's requirements. Individuals ought to seek advice from the manufacturer's standards to guarantee peak efficiency and avoid possible damage to the tools.What Safety Precautions Should I Take While Operating the Maker?

When operating a pallet wrapping maker, one ought to use proper individual safety tools, warranty proper training, preserve a clear workspace, and consistently check the equipment for any prospective dangers to ensure safe operation.Just how Do I Train New Employees to Make Use Of the Pallet wrapping Maker?

To educate brand-new staff members on the pallet wrapping device, one need to supply comprehensive presentations, comprehensive guidebooks, and hands-on practice. Regular assessments and feedback will certainly improve their abilities and guarantee safe, reliable operation.What Are the Indications That My Maker Needs Expert Servicing?

Indications indicating a demand for professional servicing consist of uncommon sounds, irregular wrapping, constant error messages, and noticeable endure elements. Prompt interest to these problems can protect against more damages and assurance height device performance.Regular upkeep checks are important for making sure the optimum performance of a pallet wrapping machine. Changing damaged parts is vital for keeping the optimal performance of a pallet wrapping device. Maintaining suitable efficiency of a pallet wrapping maker expands beyond changing worn-out parts; it additionally entails make improvements the tension and film setups. Often ignored, keeping the pallet wrapping machine tidy and lubricated is crucial for guaranteeing peak performance and longevity. Various kinds of films can normally be used with pallet wrapping devices, yet compatibility depends on the device's specifications.

Report this wiki page